Composite Repairs

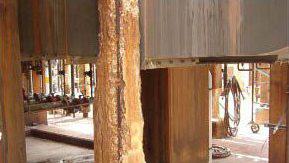

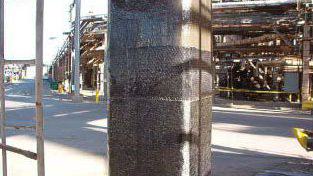

Stop and repair external corrosion, dents, gouges, erosion, or other defects in piping systems with Fortress Specialty Services field applied composite solutions. Restore piping systems to their Maximum Allowable Operating Pressure (MAOP) regardless of surface irregularities (welds, dents, sleeves etc.) piping configuration (tees, ells, reducers) internal or external wall loss. Complete and permanent repairs can also be made to vessels, tanks, welds, and infrastructure components such as bridge columns, pilings, and poles.

Fortress Specialty Services composite wrap systems meet the engineering design requirements of DOT, ASME B31.4/31.8, and ASME PCC-2 and provide our clients with a permanent repair alternative to welded sleeves, bolt on repair clamps and or pipe replacement. The Fortress Specialty Services Composite Wrap for pipeline repairs allow plant owners and operators to restore corroded or eroded pipe and piping systems to original design without the expense and hassle of extended down-times.

The structural system forms a pipe around a pipe, and each successive wrap increases the pressure rating. Its bidirectional weave allows for strength in both the hoop and axial directions experiencing little or no creep properties over time, ensuring that there is no reduction in strength. Fortress Specialty Services Composite Wrap low profile repair can be installed on tees, elbows, straight runs of pipe, confined spaces and irregular surfaces that require structural reinforcement or leak containment. The adhesive properties of the epoxy allow wrap systems to be applied to most substrates.

Typical Applications

- Dented Repairs

- Cracked Repairs

- Corroded Repairs

- Subsea / Underwater Repairs

Copyright © 2025 Fortress Specialty Services